WWS Metallformen

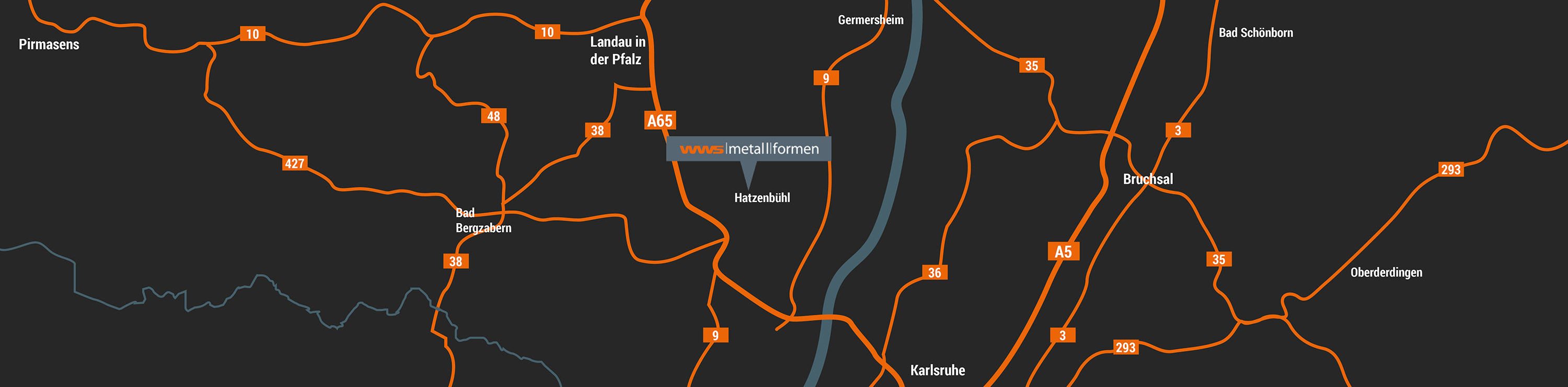

WWS Metallformen GmbH in Hatzenbuehl, Germany, provides added value by offering higher quality products, shorter completion times and greater efficiency. As an innovation-driven supplier and service provider in the metal moulding sector, we have specialized in designing, producing and testing high-precision tool moulds and in manufacturing finished complex deep-drawing and sheet metal parts for leading companies from various sectors, such as the automotive sector, aircraft industry, medical technology and consumer goods.

Seven good reasons for

choosing WWS Metallformen

1. Bring your ideas to life.

You have the idea – we realize it!

2. Save time.

Moving from prototyping to series production in only a few weeks? WWS Metallformen makes it possible!

3. Stay flexible.

Do you need prototypes or tools or even a small batch within a short period of time? We are prepared to deliver at short notice.

4. Lower your costs.

We invest heavily in the newest technology, so you have to invest less.

5. Gewinnen Sie Prozesssicherheit.

Not only do we deliver prototypes, serial parts and tools, but we also offer the necessary expertise to maximize production results.

6. Benefit from the latest technologies.

Wir sind technisch auf dem neuesten Stand. Kein Wunder, dass führende Unternehmen aus den Bereichen Automotive, Flugzeugbau, Medizintechnik und Konsumgüter auf uns vertrauen.

7. Gain a versatile partner.

Are you looking for qualified support? We are as versatile as your specific needs and provide our clients with a wide range of products and services – from design and simulation to mould making, tool testing, prototype and series production, as well as quality assurance.

0

qualified employees

0

days completion time for prototypes

0

Neue Projekte im Jahr 2022 realisiert

History

One step ahead with the latest manufacturing technologies

Shorter cutting times with a 3-D-laser

Fennek Grill

Unlimited possibilities thanks to a 5-axis-milling machine

Assembly of the AP&T 800-ton press

Downloads

Here you will find useful content to download directly.

WWS sucht engagierten Nachwuchs!

Sie wollen einen spannenden Beruf bei einem hoch innovativen Mittelständler im Metallbau erlernen? Willkommen bei WWS Metallformen! Wir wachsen seit vielen Jahren mit großem Erfolg und bieten auch über die Ausbildung hinaus interessante Perspektiven mit Zukunft.

Junge Talente fördern wir mit einer Ausbildung zur/zum:

- Industriekaufleute (m/w/d)

- Fachkräfte für Lagerlogistik (m/w/d)

- Fachkräfte Metalltechnik (m/w/d)

- Technische/r Produktdesigner/in (m/w/d)

- Werkzeugmechaniker/in (m/w/d)

Ausbildungsbeginn ist jeweils der 01.08. eines Jahres.

Erfahren Sie mehr in unserer Ausbildungsbroschüre: → Download

Neugierig geworden?

Dann freuen wir uns auf Ihre vollständige Bewerbung mit Anschreiben, Lebenslauf und Zeugnissen!

<a href="https://www.wws-metallformen.de/karriere">Direkt Online</a>

In wenigen Minuten direkt online über unser

per mail

<strong>WWS Metallformen GmbH</strong><br />Personalabteilung<br />Im Gereut 10<br />76770 Hatzenbühl